Solution

EOL Reproduction and Redevelopment

Regarding supply issues due to factory discontinuation of production, we will achieve long-term stable supplies by reproducing and redeveloping ASICs and supporting the continuation of that value.

Given the global semiconductor manufacturing trends and generational shifts, there is an increasing number of cases in which the supply of ASICs, which is crucial to our customers, has stopped, which severely impacts businesses. MegaChips breathes new life into customers’ ASICs and provide solutions to supply ASICs with a stable value.

Customer Problems

ASICs, custom SoCs developed for each customer’s specific application, have irreplaceable value to customers and are intended to be used over a long period of time. Therefore, if there is a cease in supply, it shifts the strain to customers’ product planning and parts procurement, causing a serious situation that goes beyond the mere parts supply problem.

Example of Customer Issues

- Wanting the exact same circuit, pinout, hardware, etc. as the current ASIC.

- Accepting some changes but wanting to maintain basic performance and reduce costs.

- Wanting to amend or improve the product in order to eliminate dissatisfaction with the current product.

- Wanting a stable supply for a long time.

Two Methods of EOL Reproduction

MegaChips explores the real value of ASICs that the customer wants to continue from their perspective. Whether it is an identical product, a non-negotiable feature, or an opportunity to set a stepping stone for the future, there are two ways to achieve that value.

Reproduction

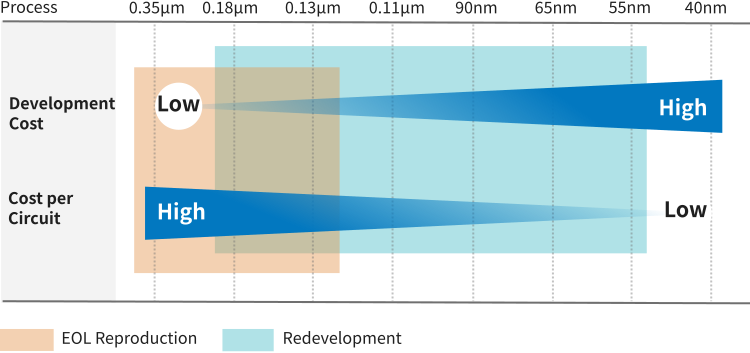

For those who want to continue to use the exact same pin layout hardware as the current ASIC, we propose optimal wafer processing, reproduction, and packages equivalent to that of the current ASIC. Depending on the conditions, such as on-board macro, circuit size, and quantity scale, the customer can select the best combination from the design rule (about 0.35um ~ 55nm) and an abundant IP lineup.

Redevelopment

By developing new ASICs that incorporate new differentiating functions while maintaining the current basic performance, we provide even more long-term advanced value. Mainly, we propose a miniaturized and cost-effective process.

Comparison of Reproduction and Redevelopment

| Method | Reproduction | Redevelopment |

| Advantage | Continued supply | Value innovation |

| ASIC development period | Good | Specification dependent |

| Development | Idea ~ RTL (mainstream) ~ GDS | |

| Unit price of ASIC | Good | Good |

| ASIC development cost | Good | Specification dependent |

| Customer’s total cost | Good | Good |

| Wafer process | Current, similar process | Die shrink (performance support) |

| Footprint | As-is | As-is |

| ASIC performance | As-is | Good |

| Add new functions | None | Good |

| MOQ | As-is | As-is |

| Customer procurement | Good | Good |

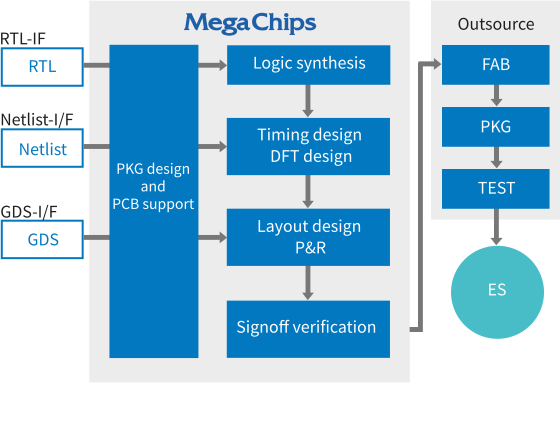

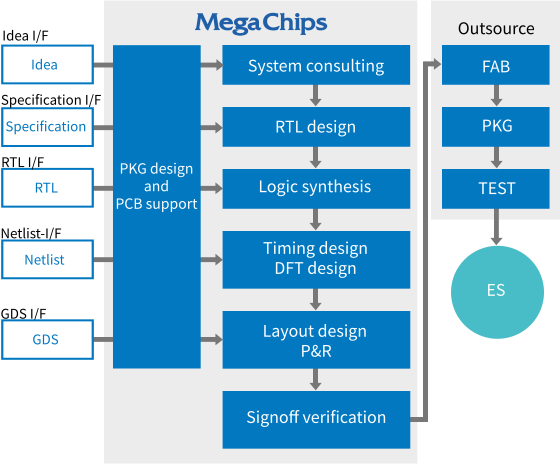

Solution of MegaChips (Development Method and Support)

The customers can make use of the advanced and flexible ASIC development method of MegaChips for both reproduction and redevelopment. In addition, under our integrated support system, which is our greatest feature, we provide a wide range of support from consultation at the idea level to production outsourcing by taking over GDS data. Collaborative analyses, such as timing analysis, SI, and PI, are also available to meet customer needs. For wafer processes, we offer the most suitable way from mature legacy nodes to cutting-edge technology, taking into account the circuit scale, onboard macros, and mask costs.

Development Process

Reproduction

Redevelopment

Wafer Process

Customer Benefits

By incorporating MegaChips ASIC development, customers can integrate optimal cost and technology to create new value and long-term stable supply beyond EOL reproduction and supply continuity.

Advantages

- Reproduction of functionally compatible products and continued supply

- New value-added ASIC with improvements and addition of new functions

- Optimal cost and technology for customers through the total solutions of MegaChips

- Long-term relationships of trust with suppliers backed by solid experience

Performance Record

EOL Reproduction

In response to customers’ requests for pin-compatible and hardware-compatible products, we proposed two kinds of processes, the conventional process and the one-generation advanced process, conducting development with the desired process. We paid special attention to the procurement of old-type packages, and when changes to the package height were not solved, we explained to customers and received their approval.

Redevelopment

We have improved the performance of conventional ASICs of customers by changing some circuit blocks, thereby helping them to broaden their applications. Since this development required several steps of the miniaturization process compared to the previous project, we proposed and adopted 55 nm, which can be mass-produced at a low unit cost, which was a step forward for EOL reproduction.

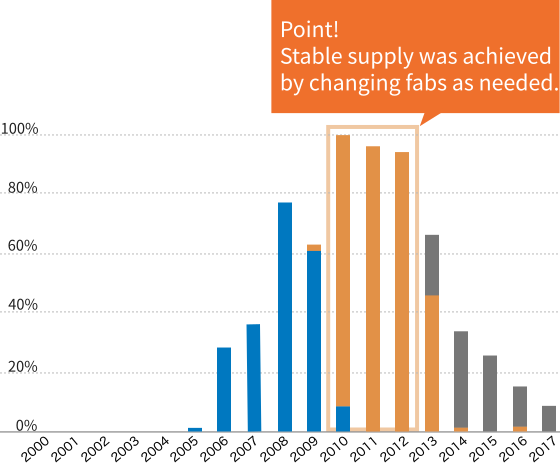

Long-Term Stable Supply

As a leading fabless company with about thirty years of expertise, we can select the most optimal process from multiple fabs. We have over fifteen years of mass-production supply at the same fab and over ten years of experience in mass production after overcoming fab changes.

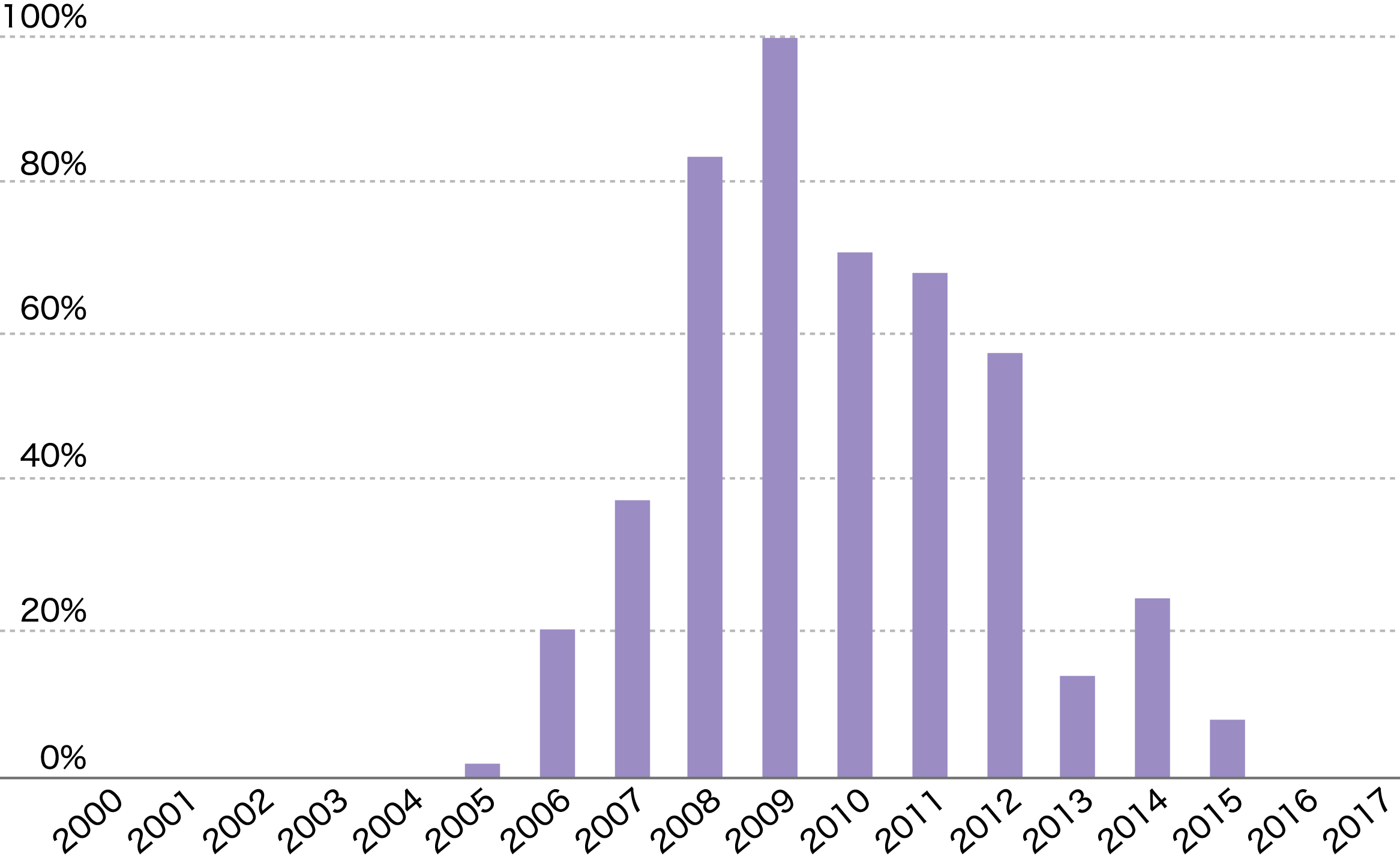

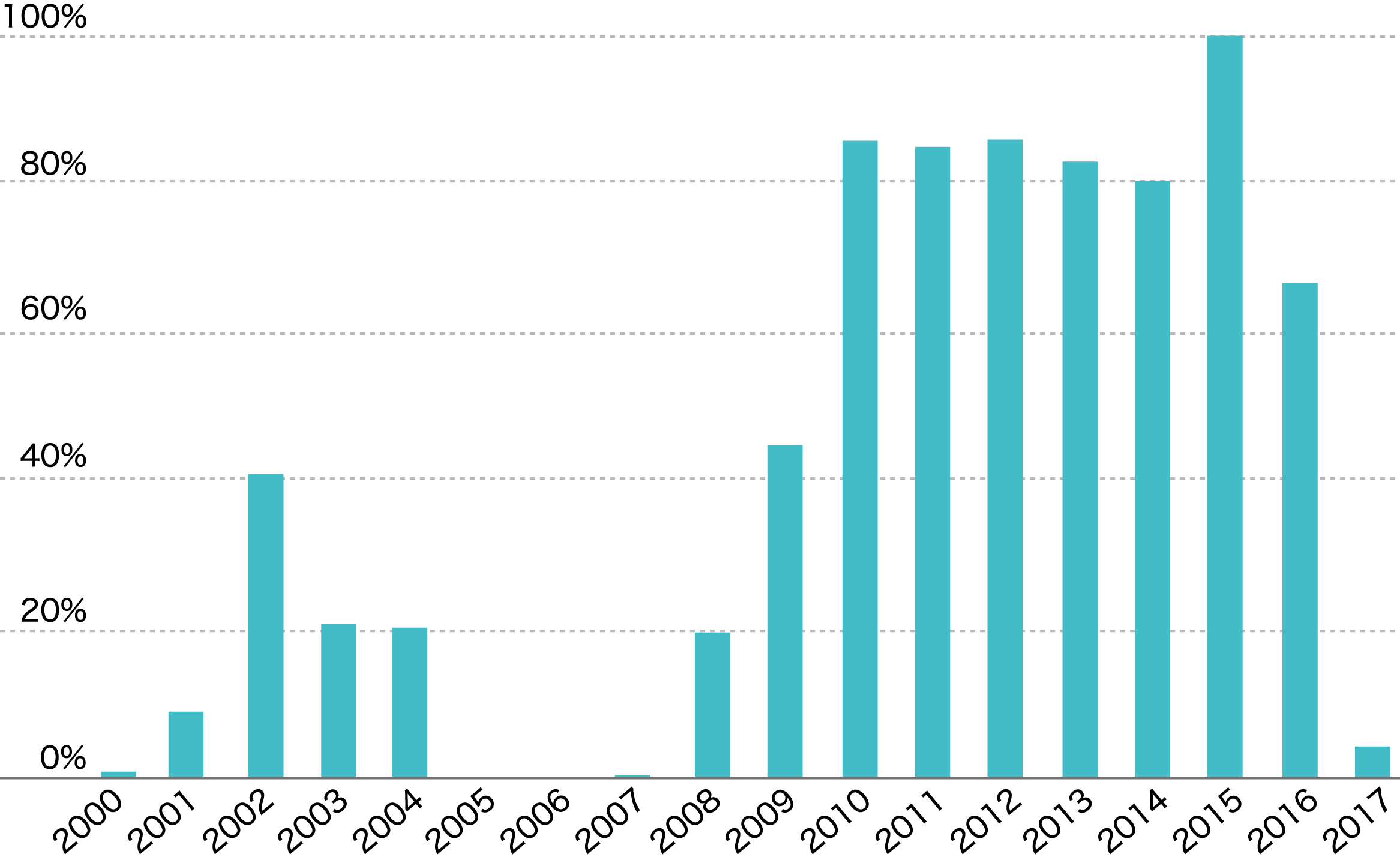

Long-Term Stable Supply of MegaChips (Shipping Quantity [relative value])

Custom LSI for Control, Company A, Network Device Manufacturer

More than 10 years of continuous supply

Custom LSI for Control, Company B, Industrial Field Manufacturer

More than 15 years of supply from the same fab

Custom LSI for Control, Company C, Industrial Field Manufacturer

More than 10 years of supply from several fabs

Customer feedback

-

Regarding the process for revision, we have received multiple proposals, so we were able to examine the pros and cons for our company in advance.

-

Thank you for reviewing the peripheral functions several times. We were able to reduce the number of parts in our implementation process and we are satisfied with the revision.